How Is CR Rubber Compound Influencing Industrial Material Selection Today?

2025-12-17

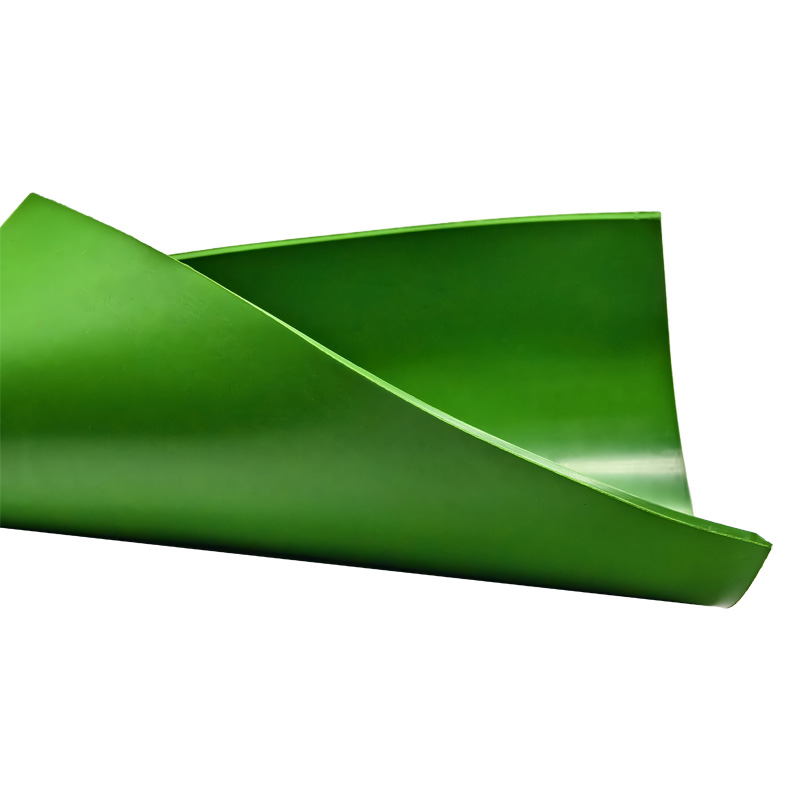

CR Rubber Compound, commonly formulated from Chloroprene Rubber (CR), is a high-performance synthetic elastomer widely specified in industrial environments that demand balanced resistance to weathering, oils, ozone, and mechanical stress. This material is frequently selected for applications where durability, safety compliance, and stable physical properties across variable operating conditions are critical. Typical use cases include automotive components, industrial hoses, conveyor systems, sealing solutions, vibration-damping parts, and protective rubber linings.

CR Rubber Compound is engineered through controlled polymer blending, filler optimization, and curing system selection. This allows manufacturers to fine-tune hardness, tensile strength, elongation, and environmental resistance without compromising processing stability. Unlike general-purpose rubber materials, CR-based compounds are often specified where both mechanical integrity and environmental resistance must coexist within a single elastomer system.

Technical Parameters and Material Characteristics

From a professional engineering perspective, CR Rubber Compound is evaluated based on standardized physical, chemical, and thermal metrics. These parameters ensure consistency in production, predictability in application performance, and compliance with international specifications such as ASTM, ISO, and DIN standards.

Below is a consolidated overview of typical technical parameters associated with industrial-grade CR Rubber Compound. Actual values may be adjusted based on formulation and application requirements.

| Parameter | Typical Range | Test Standard |

|---|---|---|

| Polymer Type | Chloroprene Rubber (CR) | ASTM D1418 |

| Hardness (Shore A) | 40 – 80 | ASTM D2240 |

| Tensile Strength | 8 – 20 MPa | ASTM D412 |

| Elongation at Break | 200% – 500% | ASTM D412 |

| Operating Temperature | -40°C to +120°C | Internal Method |

| Density | 1.20 – 1.45 g/cm³ | ASTM D297 |

| Compression Set (70°C, 24h) | ≤ 35% | ASTM D395 |

| Aging Resistance | Stable after heat and ozone exposure | ASTM D573 / D1149 |

CR Rubber Compound exhibits inherent resistance to ozone cracking and atmospheric aging, making it suitable for both indoor and outdoor applications. Its moderate oil resistance allows use in environments with incidental contact with lubricants or fuels, while its flame-retardant nature supports compliance in safety-regulated industries.

From a processing standpoint, CR compounds demonstrate stable extrusion and molding behavior, supporting compression molding, transfer molding, and injection molding processes. This versatility contributes to consistent dimensional control and surface quality in finished rubber parts.

How CR Rubber Compound Supports Performance Consistency Across Industries

How does CR Rubber Compound maintain performance consistency across such a wide range of industrial applications? The answer lies in its molecular structure and formulation adaptability.

The chloroprene polymer backbone provides a balanced polarity, which directly influences resistance to environmental stressors such as UV exposure, oxygen, and ozone. This structural stability reduces premature degradation, particularly in dynamic applications where flexing and compression are continuous.

Additionally, CR Rubber Compound can be compounded with various fillers, plasticizers, and curing agents to match specific operational demands. For example, mineral fillers enhance dimensional stability, while reinforcing agents improve tear resistance in mechanically stressed components. Curing systems are selected to balance crosslink density with elasticity, ensuring predictable deformation behavior under load.

Electrical insulation properties further extend the material’s usability in cable jackets, protective covers, and equipment housings. Combined with low-temperature flexibility, CR Rubber Compound performs reliably in both temperate and cold environments without excessive stiffening.

Another critical factor is compliance. CR Rubber Compound formulations are often designed to meet regional regulatory requirements, including RoHS, REACH, and industry-specific safety standards. This regulatory alignment simplifies global supply chains and reduces qualification cycles for OEMs and Tier 1 suppliers.

Common Questions About CR Rubber Compound (FAQ)

Q: How does CR Rubber Compound differ from general-purpose rubber materials in industrial use?

A: CR Rubber Compound is formulated to deliver a balanced profile of weather resistance, mechanical stability, and processing reliability. Unlike general-purpose rubber, it maintains structural integrity under ozone exposure, moderate oil contact, and temperature variation, making it suitable for regulated and long-life applications.

Q: How is CR Rubber Compound selected for specific operating environments?

A: Selection is based on defined performance criteria such as hardness, temperature range, compression behavior, and environmental exposure. Engineers evaluate these parameters against application requirements, then specify a CR compound formulation that aligns with mechanical loads, service life expectations, and compliance needs.

Conclusion and Industry Outlook

CR Rubber Compound continues to play a critical role in industrial material selection due to its formulation flexibility, predictable performance, and compatibility with global manufacturing standards. Its ability to function reliably across diverse operating conditions supports long-term component stability and supply chain efficiency.

As industrial specifications evolve toward higher safety, durability, and regulatory compliance, CR Rubber Compound remains a practical and scalable elastomer solution. Material developers and OEMs increasingly value compounds that can be customized without sacrificing consistency, making CR-based systems a stable choice for both current production and future platform planning.

SLD RUBBER specializes in the development and supply of CR Rubber Compound engineered for industrial applications requiring controlled quality and technical precision. With a focus on formulation accuracy, testing consistency, and application alignment, SLD RUBBER supports customers across automotive, industrial, and infrastructure sectors.

For technical specifications, custom compound development, or application consultation, contact us to discuss how CR Rubber Compound solutions from SLD RUBBER can support specific project requirements and long-term production goals.