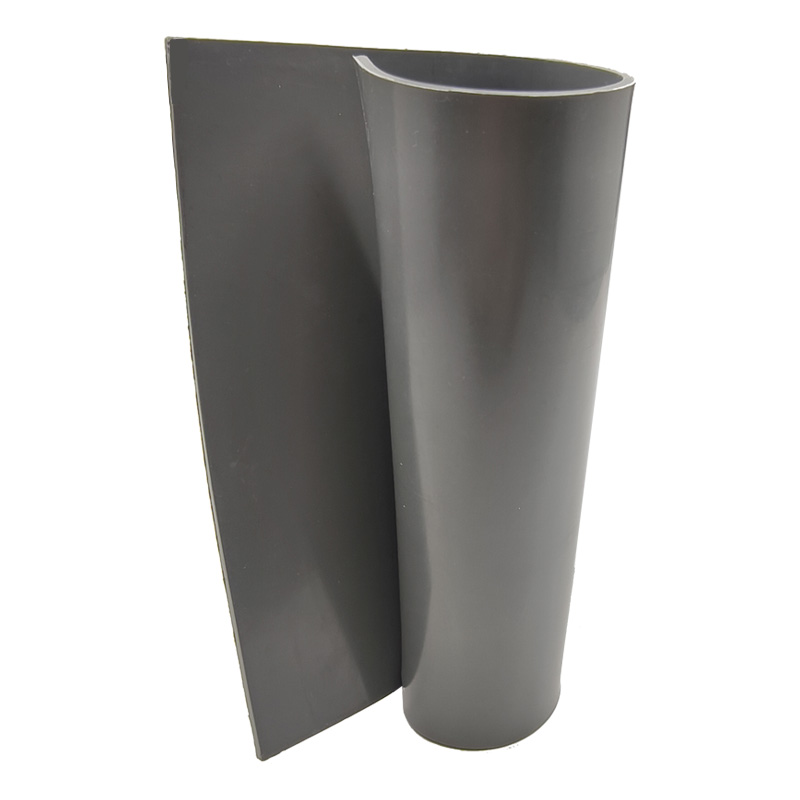

IR Rubber Compound for Hoses

As a professional manufacturer, Jiashima Rubber Solutions is committed to providing you with IR Rubber Compound for Hoses, which ingeniously combines the excellent properties of isoprene rubber with other functional additives to precisely meet the needs of your specific application scenarios. At the same time, we are also committed to providing you with the best after-sales service and ensuring timely delivery.

Send Inquiry

This IR Rubber Compound for Hoses produced by our Jiashima factory is a kind of "compound rubber with polyisoprene rubber (IR) as the base material, specially strengthened for the usage characteristics of rubber hoses in dynamic bending and low-temperature environments". Its core value lies in the fact that "it possesses excellent elasticity and flexibility comparable to natural rubber, while performing better in terms of aging resistance, ozone resistance and processing stability, and maintaining uniform quality." As a "high-performance flexible tube body material", it is used to manufacture high-end rubber hoses that need to maintain flexibility and safety for a long time in harsh environments.

Feature

The IR Rubber Compound for Hoses produced by us gives people the feeling of "extreme softness" and "delicacy".It is usually white and very pure in texture. When kneading by hand, it can feel softer and smoother than other rubbers, and there is almost no blocking feeling.When stretched, it bounces back extremely quickly and exhibits remarkable elasticity. This delicate touch and outstanding flexibility are precisely the signature features of IR material.

How to maintain

The maintenance of our IR Rubber Compound for Hoses is mainly reflected in the storage link.Please store the compound in a cool, ventilated, dry warehouse, avoid direct sunlight, away from heat and ignition, and strictly prevent contact with any chemicals or pollutants. Please use it within the specified shelf life to ensure its best processing performance and final product performance.

Application scenarios

Our IR Rubber Compound for Hoses is the "high-end choice" in all hose fields that have "extreme requirements for flexibility and low-temperature performance". It is widely used in automotive brake tubes, power steering tubes, air conditioning tubes and other rubber hoses that require high dynamic safety. Hydraulic pipes for construction machinery; And various pneumatic pipes and oil pipelines used in cold regions.

Personnel advantage

Many of our team members are "senior rubber formula engineers and experts familiar with automotive hose standards". When you come for consultation, our staff can not only provide you with a quotation, but also recommend the most suitable formula for you based on the specific application of your rubber hose (such as whether it is used in a braking system or an air conditioning system). Our services are based on a profound understanding of rubber science and automotive engineering standards.