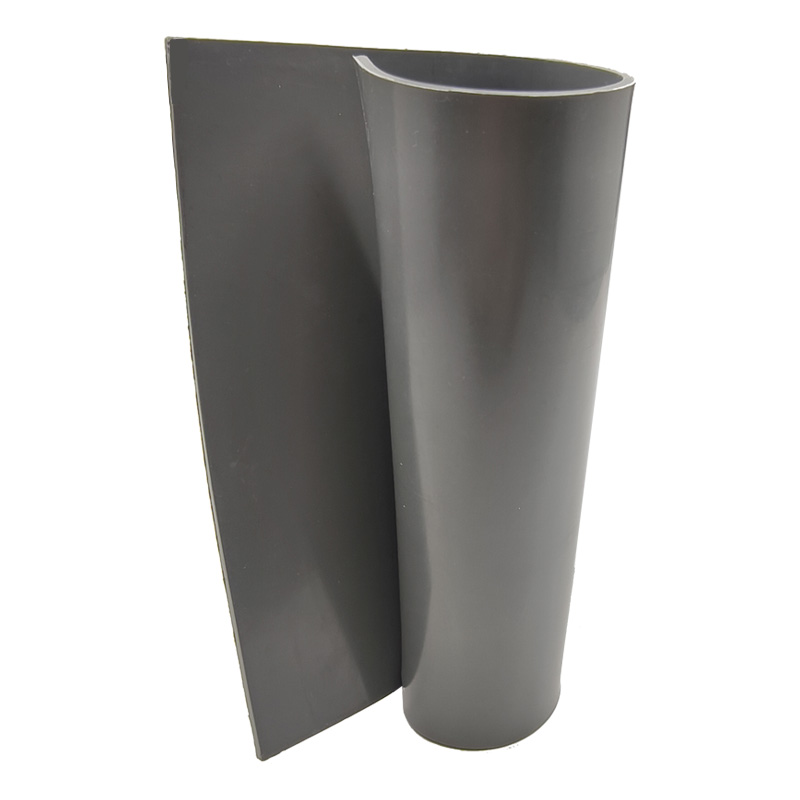

IR Rubber Compound for Medical Product

If you are looking for IR Rubber Compound for Medical products made in China, I believe that Jiashima rubber solutions must be your best choice. We have been deeply involved in this industry for over 30 years. We are confident that our capabilities and experience will surely be of assistance to you.

Send Inquiry

This IR Rubber Compound for Medical Product produced by our Jiashima factory is a kind of "compound rubber based on synthetic polyisoprene rubber (IR), specially designed for the extreme requirements of purity, biocompatibility and soft touch in the medical field". Its core value lies in the fact that "its molecular structure and performance are extremely similar to those of natural rubber, thus possessing extraordinary softness and elasticity. However, as a synthetic material, it does not contain the proteins in natural rubber that may cause allergies, ensuring extremely high biological safety." As a "high-purity biocompatible material", it directly enhances the comfort of using medical products and the safety guarantee of patients.

Application scenarios

This IR Rubber Compound for Medical Product is the "core material" in all medical fields that have "extreme requirements for comfort and biosafety". It is widely used in the tube body or soft head of high-end medical catheters, sealing plugs and gaskets on medical equipment, contact layers in wound care products, and rehabilitation devices that need to simulate the touch of human tissues.

Feature

The first impression this IR Rubber Compound for Medical Product gives is "extreme softness" and "purity". It is usually white or very light in color, with a fine texture and a warm touch, and hardly has the "stiffness" of ordinary rubber. Gently press it with your fingers, and you can feel its softness and elasticity like skin. This inner purity and flexibility are the physical basis for its suitability for medical applications.

Performance

This IR Rubber Compound for Medical Product pursues an "ultimate softness and comfort" and "top-notch biocompatibility". Its greatest trump card is that the medical products made from it, such as catheters or sealing plugs, can provide an unparalleled soft touch, greatly enhancing the patient's comfort, especially in applications that need to come into contact with the skin or mucous membranes. Meanwhile, it has passed strict cytotoxicity, sensitization and irritation tests to ensure it is safe and harmless to the human body. In addition, it also has excellent processing performance and is suitable for the production of precision medical products.

Company advantages

Because our company is "a professional manufacturer with a profound understanding of medical device regulations and biomaterials science". We have a thorough understanding of the entire process requirements for medical products, from material selection to final market launch. We have a production environment and testing equipment that meet medical-grade requirements, and can provide you with "one-stop" technical services ranging from material development to regulatory support.